-

Hydrogen plays a key role on the road to CO2-free mobility, as it can be used to gradually replace fossil fuels, making the ambitious climate targets achievable in the first place. The ongoing development of hydrogen technologies and the rising prices of fossil fuels mean that the direct use of hydrogen in fuel cells or combustion engines is becoming increasingly economical. In addition to these two central technologies for converting chemically bound energy into electrical or mechanical energy, the production, storage and distribution of hydrogen will play an equally important role in a future hydrogen economy.

The "Hydrogen Technologies for Transport" (H2T2) laboratory at OTH Regensburg aims to address the challenges of hydrogen supply (production and storage) in addition to the field of energy conversion.

The laboratory has comprehensive measurement technology and testing facilities for investigating various hydrogen technologies. Appropriate test cells enable safe research operations with hydrogen and also offer industrial partners from the research and development sector the opportunity to examine existing and future technologies, for example with regard to hydrogen compatibility.

-

The combustion of fossil fuels in the construction and transportation sector releases large amounts of carbon dioxide (CO2), which further contributes to climate change. Due to the low energy density of battery storage systems, areas such as trucking, air traffic, shipping and construction machinery can only be electrified to a limited extent, which is why other CO2-neutral solutions must be found.

In the laboratory for combustion engines and exhaust gas aftertreatment, research is being conducted into a variety of CO2-neutral and low-emission fuels for combustion engines. At the heart of the research work are experimental studies with various fuels, fuel mixtures and exhaust gas aftertreatment concepts on a single-cylinder research engine or various multi-cylinder engines (passenger cars, commercial vehicles, industrial/construction machinery engines). The experimental research is accompanied by 0D/1D simulations of the engine process and the hydraulics of injection systems.

Due to differences in the chemical and physical properties, these fuels cannot be easily integrated into existing engines. The compatibility of the injection system with the fuel and the influence of viscosity, density, etc. on injection, mixture formation and combustion are researched in depth in the combustion engines and exhaust gas aftertreatment laboratory.

Our core competencies in engine optimization and research into alternative fuels:

- Investigation of a wide range of fuels and fuel mixtures/blends on the engine test bench

- Adaptation of the engine control unit to the alternative fuels (calorific value, ignition properties, ...)

- Performance and emission measurements on the engine test bench and evaluation/comparison of fuels based on measurement data with reference fuels (diesel, gasoline)

- Combustion process development and adaptation of engine components (pistons, combustion chamber geometry, turbocharging, ...)

- Determination and analysis of all exhaust gas components using mass spectrometry, Fourier transform infrared spectrometer (FTIR), exhaust gas measurement system and particle measurement technology (size distribution, mass, number)

- Extensive thermodynamic analyses to gain an in-depth understanding of the combustion process

- Basic investigations into injection behavior (spray, hydraulics) and injection components using system test benches

- Hardware adaptation and testing of modified injection components on the engine and injection test bench

- Effects on exhaust gas aftertreatment/development of new exhaust gas aftertreatment concepts

- Research into new diagnostic options using software and sensors (fuel detection, exhaust gas sensors, ...)

-

Exhaust gas aftertreatment is an important part of a combustion engine. Legislation is making the limit values for exhaust emissions ever stricter in order to improve air quality. The laboratory has a wide range of measuring equipment at its disposal to research optimizations and adjustments to the combustion engine and exhaust aftertreatment system.

Although combustion engines and their control systems are constantly being optimized with regard to the formation of pollutants, the formation of harmful exhaust gas components cannot be completely avoided. Exhaust gas aftertreatment systems are essential to prevent these pollutants from being released into the environment. In order to develop more environmentally friendly combustion engines and thus comply with the strictest emission limits, we are researching exhaust gas aftertreatment systems. Our range of research in this area includes various investigations into sensor technology and catalysis on both petrol and diesel engines. The projects help to further increase the efficiency of aftertreatment over the largest possible areas of the engine map, even under unfavorable conditions such as cold start phases.

-

Due to the complexity of the processes during the combustion process and the poor accessibility of the combustion chamber, many state variables and processes in the engine cannot be recorded and described, or only with enormous effort. Engine simulation makes it possible to estimate non-measurable variables and to investigate and optimize new combustion process concepts and components cost-effectively and at a very early stage of engine development.

For example, 3D CFD can be used to investigate and optimize the flow field in the combustion chamber, which is largely responsible for the mixture preparation of the engine. Another example is the determination of the residual gas content using 1D charge cycle simulation. This value is practically impossible to measure, but is very important in terms of pollutant emissions and efficiency. There are many examples of simulation applications such as these, which is why simulation methods have become an integral part of modern engine development.

The 1D simulation is the most common type of simulation. It combines sufficient accuracy with manageable computational effort. For example, development engineers can use computer-aided methods to test the effect of different turbocharger combinations within a few minutes without leaving the office. The scope of investigation is not limited to combustion, but can also be extended to engine and vehicle components such as injection systems, exhaust gas aftertreatment systems, battery packs or fuel cells. Overall system simulations are also possible. For example, modern 1D simulation environments can be used to model an entire vehicle so that it can then be tested virtually in traffic with the help of live traffic data.

The use of synthetic fuels in diesel and petrol engines is currently being investigated at OTH Regensburg. The 1D simulation is an important part of the combustion analysis as well as the injection system development. The aim is first to map the actual state of combustion of synthetic fuels in order to subsequently derive optimizations and optimization recommendations for engine components that enable optimal use of the new fuels.

-

The formation of pollutant emissions and the efficiency of a combustion engine are significantly influenced by the preparation of the fuel-air mixture in the combustion chamber. As the injection system acts as a link between the fuel in the tank and the combustion chamber, it has a direct influence on the combustion quality, which means that optimum matching of the components to the respective fuel is crucial.

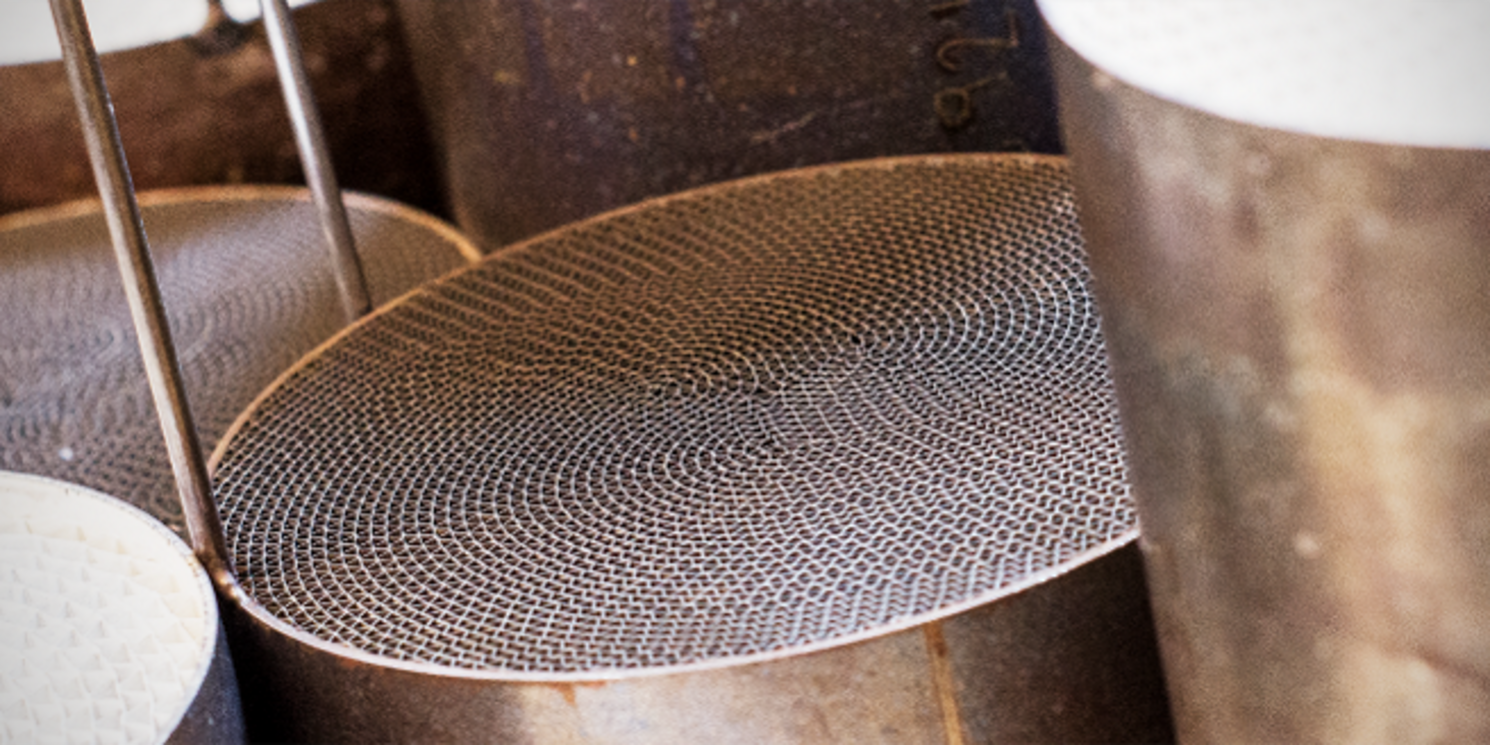

In order to investigate the influence of various fuel properties (physical/chemical) and system components (nozzles, high-pressure pumps) on the hydraulic injection behavior and mixture formation, the Laboratory for Internal Combustion Engines has the following expertise and measuring methods at its disposal.

Hydraulic investigation/volume behavior

The combustion engine laboratory has an HDA injection rate analyzer from Moehwald GmbH for the hydraulic measurement of injection systems. This can be used to measure injection rates and injection masses of various nozzles and injection systems. The measuring system is a fuel-independent measuring principle, which is why it is very well suited for investigating alternative fuels. This means that the influence of various fuel properties such as viscosity on the injection system behavior can be investigated in detail.

The following results can be generated/derived at the OTH:

- Derivation of quantity maps (application)

- Effect of multiple injections on system dynamics (e.g. ballistic operation)

- Investigation of the injector hydraulics (post-injection, shot-to-shot scattering, rate curve)

- Influence of alternative fuels on injection behavior

- Optimization of system components (nozzle/pump development)

- Data for the validation of hydraulic simulation models

Optical measurement methods

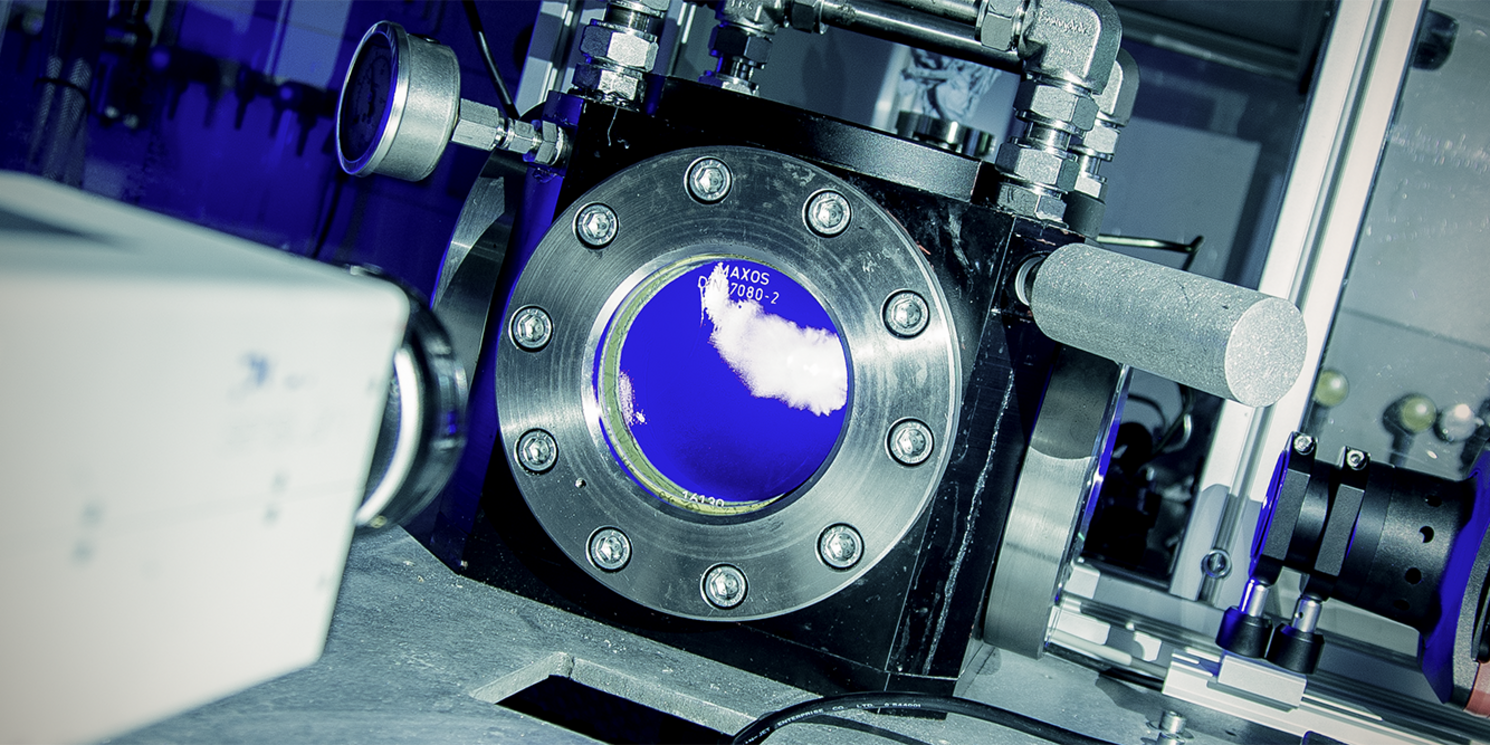

A high-pressure chamber with optical access is available in the combustion engine laboratory at OTH Regensburg for closer examination of the injection jet and its decay. The chamber can be temperature-controlled in order to map evaporation effects and the influence of different back pressures on the injection can be simulated by pressurizing it with nitrogen. Various cameras, optics and exposure systems are available in the laboratory for optical imaging.

The following parameters can be determined

- Jet penetration depth

- Beam break-up angle

- Jet velocity

- Spray frequency distribution

- Droplet sizes

Further advantages of the optical measuring method

- Visualization of the injection process

- Assessment of jet decay under various boundary conditions

- Optimization of mixture formation away from the engine

- Comparative assessment of injectors

- Obtaining experimental results for the validation of simulation models

At the OTH Regensburg, both the shadowgraph technique and the schlieren technique are used in the analysis of injection jets.

-

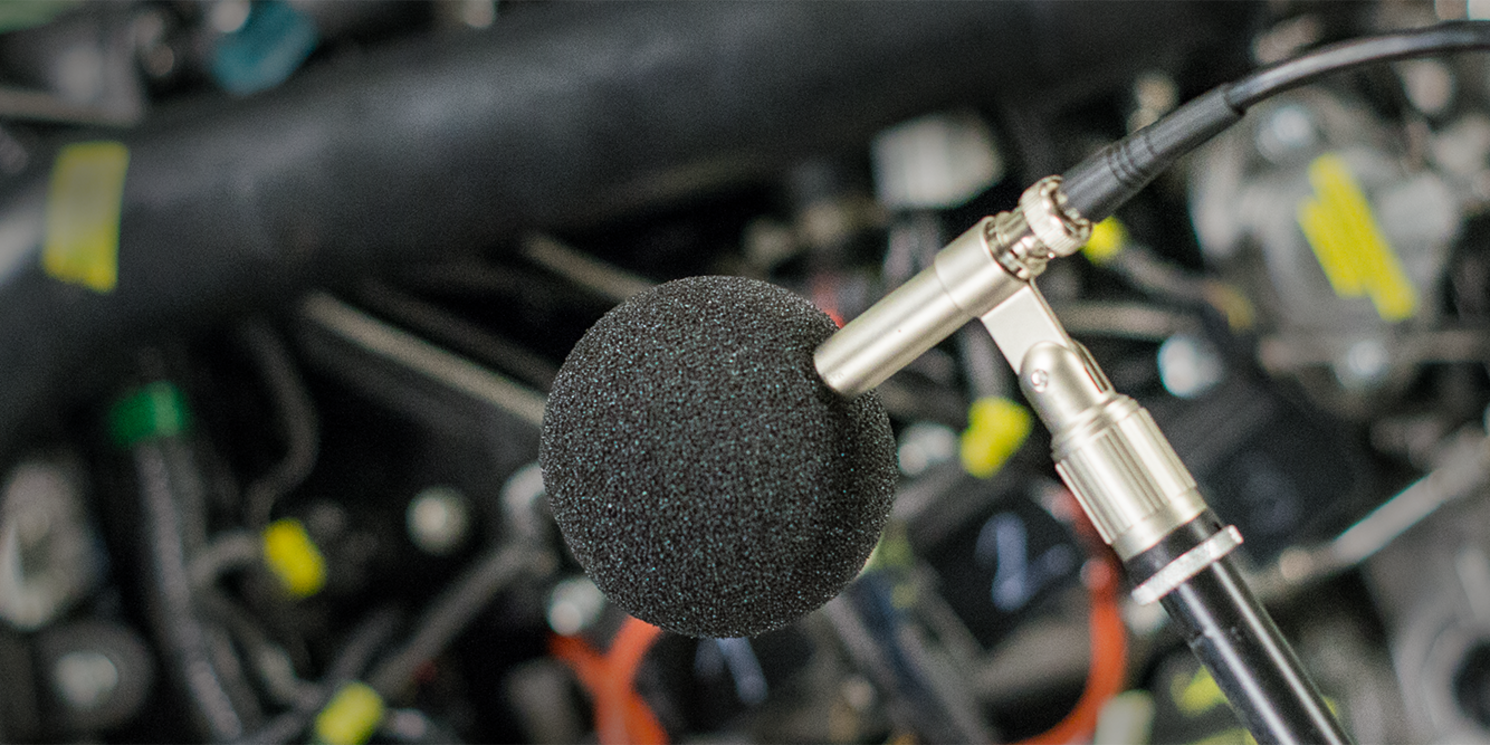

The noise spectrum of a vehicle is complex due to the number of components and is primarily dominated by the respective powertrain. Optimization and analysis at component level play an important role here, as does analysis of the overall noise.

For example, the noise spectrum of a vehicle powered by an internal combustion engine is not only characterized by the combustion process, but also by the noise emitted by individual components such as gearboxes, injectors or fuel pumps.

The use of hybrid or all-electric drive concepts and, in particular, electric motors with inverters and gearboxes, which have a very sonorous character, also pose new challenges due to a changed noise spectrum.

As the automotive industry is faced with ever-increasing customer requirements in terms of comfort, NVH (Noise Vibration Harshness) analysis is an essential part of development work. This means that the systems are not only optimized with regard to certain primary functions, but also with regard to secondary functions such as noise emission.

The laboratory has comprehensive measurement equipment to determine the noise spectrum. In addition to classic microphone and acceleration measurements, investigations can also be carried out using an acoustic camera, laser vibrometer and binaural technology in the low-reflection rooms at OTH Regensburg.

In the field of vehicle acoustics, the laboratory deals with the following topics in brief:

- Determination of the noise characteristics of complete and partial systems

- Acoustic optimization of complete and partial systems

- Development of test procedures for complete and partial systems

- Development of acoustic test benches for complete and partial systems

-

Kunstkopf im reflexionsarmen Raum. Foto: OTH Regensburg / Anna Rieger Psychoacoustics - How we really perceive sounds

Why do we perceive a Beethoven symphony differently from the sound of a jackhammer, even if both have a similar frequency spectrum?

The answer lies in psychoacoustics - the science that deals with the connection between physical sound measurement and human perception.

What is psychoacoustics?

Psychoacoustics investigates how our hearing system perceives sounds. This involves not only measurable variables such as sound pressure level, but also subjective perceptions such as loudness or pleasantness. For example, our hearing perceives different frequencies at the same sound pressure level at different volumes - an effect that is caused by the structure and function of the human hearing system.

Areas of application of psychoacoustics

Psychoacoustics is a central component of NVH (Noise, Vibration, Harshness) development in the automotive sector and in product design in general. Product noise is a key quality feature that influences customer perception and product evaluation. Development engineers use psychoacoustic analysis models, which serve as digital twins of human auditory perception and thus as a tool to specifically optimize sound characteristics.

How do psychoacoustic analysis models work?

These models are developed through listening tests with test subjects using psychophysical methods and simulate the function of human hearing. Digital signal processing is used to generate metrics such as loudness or pleasantness, which are used to optimize a (technical) product.

Research at the OTH Regensburg

OTH Regensburg is researching how alternative forms of drive - in particular electric and hybrid drives - are perceived acoustically. The aim is to optimize the perceived noise quality using digital tools and specific analysis parameters.

Main research areas:

- Basic research into hearing mechanisms

- Hearing tests for the quantitative description of subjective sound perception

- Development of psychoacoustic analysis methods for sound design

- Psychoacoustic analysis of complete and partial systems

-

In situ / on-board diagnostic systems are used across all industries to monitor the condition of a system or the state of damage or health. In addition to optical methods, so-called "acoustic emission" systems are also used. Systems are monitored via changes in their vibration spectrum.

In the automotive sector, increasing electrification in vehicles, software-guided control and regulation and the growing complexity of drive systems are placing high demands on diagnostics and monitoring during driving.

For example, modern vehicles with gasoline engines are equipped with a gasoline particulate filter due to the tightening of exhaust emission standards. Legislation and manufacturers require reliable on-board diagnostics to monitor this exhaust-relevant component. However, there is currently no diagnostic and monitoring procedure that meets all requirements. A methodology must therefore be developed that reliably records and evaluates all relevant operating states (soot and ash loading, damage and presence monitoring). This enables integrated lifetime management (predictive maintenance) and thus an increase in perceived product and service quality.

Accelerometers with a high bandwidth can be used to implement such a system. Significant differences in the spectrum can be used to detect changes in condition.

In the area of condition monitoring, the laboratory deals with the following topics in brief:

- Measurement setup for recording the relevant vibration spectra

- Measurement and analysis of the vibration spectra

- Development of suitable diagnostic procedures and characterization of various conditions